Common Problems with Marine Electrical Systems: Troubleshooting and Solutions

An unexpected failure of your boat's electrical system can not only dampen a lovely cruise out in the open waters, but it can also propel you into potentially dangerous scenarios. If you've been facing flickering lights, random power losses or unusual battery drain, you're likely dealing with marine electrical system issues. This guide will shed light on common problems with marine electrical systems, offering troubleshooting tips and practical solutions to keep your aquatic adventure smooth and safe. Get ready to save yourself from unwanted distress by becoming your own boat's electrician!

Common problems with marine electrical systems include corrosion, faulty wiring, and overloading of the electrical system. These issues can lead to malfunctions or failures of essential equipment such as navigation lights, bilge pumps, and electronic instruments. Regular maintenance, including battery checks, wiring inspections, and services by qualified technicians, is crucial for ensuring the safety and reliability of a boat's electrical system. Taking preventative measures such as regularly cleaning and maintaining electrical connections can help prevent corrosion caused by saltwater.

Corrosion in Marine Electrical Systems

Marine electrical systems are essential for the smooth and efficient operation of boats, powering various equipment and systems onboard. However, these systems are susceptible to a common problem: corrosion. Corrosion occurs when metal components in the electrical system come into contact with saltwater or moisture, leading to gradual deterioration and potential failure of the system.

Corrosion can manifest in different forms, such as rust, pitting, or oxidation, depending on the type of metals involved. It tends to occur more frequently in marine environments due to the high salt content present in seawater. This saltwater acts as an electrolyte, facilitating the electrochemical reactions that cause corrosion.

Boat owners must be vigilant in combating corrosion in their electrical systems. Ignoring the issue can lead to significant problems, including electrical failures and compromised safety on the water.

Understanding the impact of corrosion on marine electrical systems is crucial for boaters to grasp the importance of proactive prevention measures and regular maintenance.

The Impact of Corrosion

Corrosion can have detrimental effects on marine electrical systems, impacting both their performance and longevity. Here are some key ways in which corrosion can affect these systems:

- Reduced Conductivity: When corrosion occurs on wiring or connectors, it can impede the flow of electricity by creating resistance. This increased resistance leads to voltage drops and inefficient power delivery to equipment onboard the boat. As a result, appliances may not function optimally or may experience intermittent power issues.

- Increased Heat Generation: Corroded connections often generate more heat than their non-corroded counterparts due to higher resistance levels. Excessive heat can further contribute to wire insulation degradation and increase the risk of electrical fires or equipment damage.

- Intermittent Electrical Failures: Corrosion can create intermittent connections that vary with environmental conditions. This unpredictability can lead to sudden electrical failures, impacting critical systems such as navigation lights, bilge pumps, or communication devices when you least expect it.

- Reduced Lifespan of Components: Corrosion accelerates the wear and tear on electrical components, diminishing their lifespan. This can result in frequent replacements or repairs, leading to increased costs and inconvenience for boat owners.

Addressing the impact of corrosion requires a proactive approach that includes regular inspections, proper installation techniques, and the use of corrosion-resistant materials. Applying protective coatings, employing dielectric greases, and ensuring good wire insulation are some measures that can mitigate the damaging effects of corrosion.

Now that we understand the impact of corrosion on marine electrical systems, let's explore effective solutions to combat this pervasive problem.

Solutions to Combat Corrosion

Corrosion is a common issue that can plague marine electrical systems. The presence of saltwater and moisture can lead to the formation of corrosive substances, which can deteriorate connections and compromise the functionality of electrical components. However, there are several solutions available to combat corrosion and maintain the integrity of your boat's electrical system.

One effective solution is regular cleaning and maintenance of electrical connections. By using a wire brush or an abrasive pad, you can remove any buildup of corrosion on battery terminals, connectors, and other electrical contacts. Inspect these connections regularly for signs of corrosion and clean them as needed. Applying an anti-corrosion spray or dielectric grease after cleaning can provide an additional layer of protection.

Another method to combat corrosion is the use of sacrificial zinc or aluminum anodes. These anodes are installed in strategic locations on the boat, such as the propeller shaft, engine block, and outboard motor. They attract corrosion-causing elements away from critical electrical components, sacrificing themselves in the process. Regularly inspect and replace these anodes as needed to ensure their effectiveness.

Imagine you have a sailboat that spends most of its time in saltwater environments. After noticing some intermittent issues with your navigation lights, you decide to inspect the connections thoroughly. Upon removing the electrical cover, you discover a thick layer of greenish-blue corrosion on both the positive and negative terminals. Using a wire brush, you carefully clean off the corrosion and apply an anti-corrosion spray before reassembling everything. This proactive approach helps prevent future issues caused by corrosion.

Additionally, sealing electrical connections with heat shrink tubing or waterproofing compounds can provide added protection against moisture intrusion. Ensure all connections are properly insulated to prevent water from seeping in and causing damage over time. Regularly check for any signs of wear or damage on insulation and promptly address any issues before they exacerbate.

By implementing these solutions to combat corrosion, you can significantly extend the lifespan of your marine electrical system and avoid costly repairs down the line. Regular maintenance and proactive measures are essential to keep your boat's electrical connections in optimal condition.

Wiring Issues: Common Problems and Solutions

Wiring issues can be a source of frustration and safety concerns in marine electrical systems. Faulty wiring can lead to various problems, including intermittent power, short circuits, and even potential electrical fires. It is crucial to address wiring problems promptly to ensure the reliability and safety of your boat's electrical system. Let's explore some common wiring issues and their solutions.

One common problem is frayed or damaged wires. Over time, exposure to the harsh marine environment, vibrations, and general wear and tear can cause insulation on wires to become brittle or worn. This exposes the conductive wire underneath and increases the risk of short circuits or electrical failures.

To address frayed or damaged wires, it is necessary to identify the affected areas and replace them with high-quality marine-grade wiring. Ensure proper sizing of wires based on current requirements, use heat shrink tubing for insulation, and secure connections with appropriate crimps or soldering techniques.

Another issue that arises with wiring is improper connections or loose terminals. Loose terminals can lead to poor conductivity, which can cause voltage drops or result in overheating at connection points. It is essential to periodically inspect all electrical connections throughout your boat's wiring system and tighten any loose terminals.

Imagine you notice that your VHF radio intermittently loses signal during critical communication. After investigating, you discover a loose connection at the antenna terminal on the back of the radio. By simply tightening this connection securely using a screwdriver, you restore a solid connection and eliminate those frustrating signal interruptions.

Proper labeling of wires is also crucial for troubleshooting and preventing potential mistakes during installations or repairs. Use color coding or labeling methods to identify wires and ensure clear documentation of wiring diagrams for future reference.

Think of your boat's wiring system as the nervous system of your vessel. Just like nerves carry signals throughout your body, the wiring system carries electrical power to various components on your boat. Ensuring that these "nerves" are in good condition and appropriately connected is essential for the overall functionality and safety of your marine electrical system.

By addressing common wiring issues promptly and implementing proper solutions, you can maintain a reliable and safe electrical system onboard your boat.

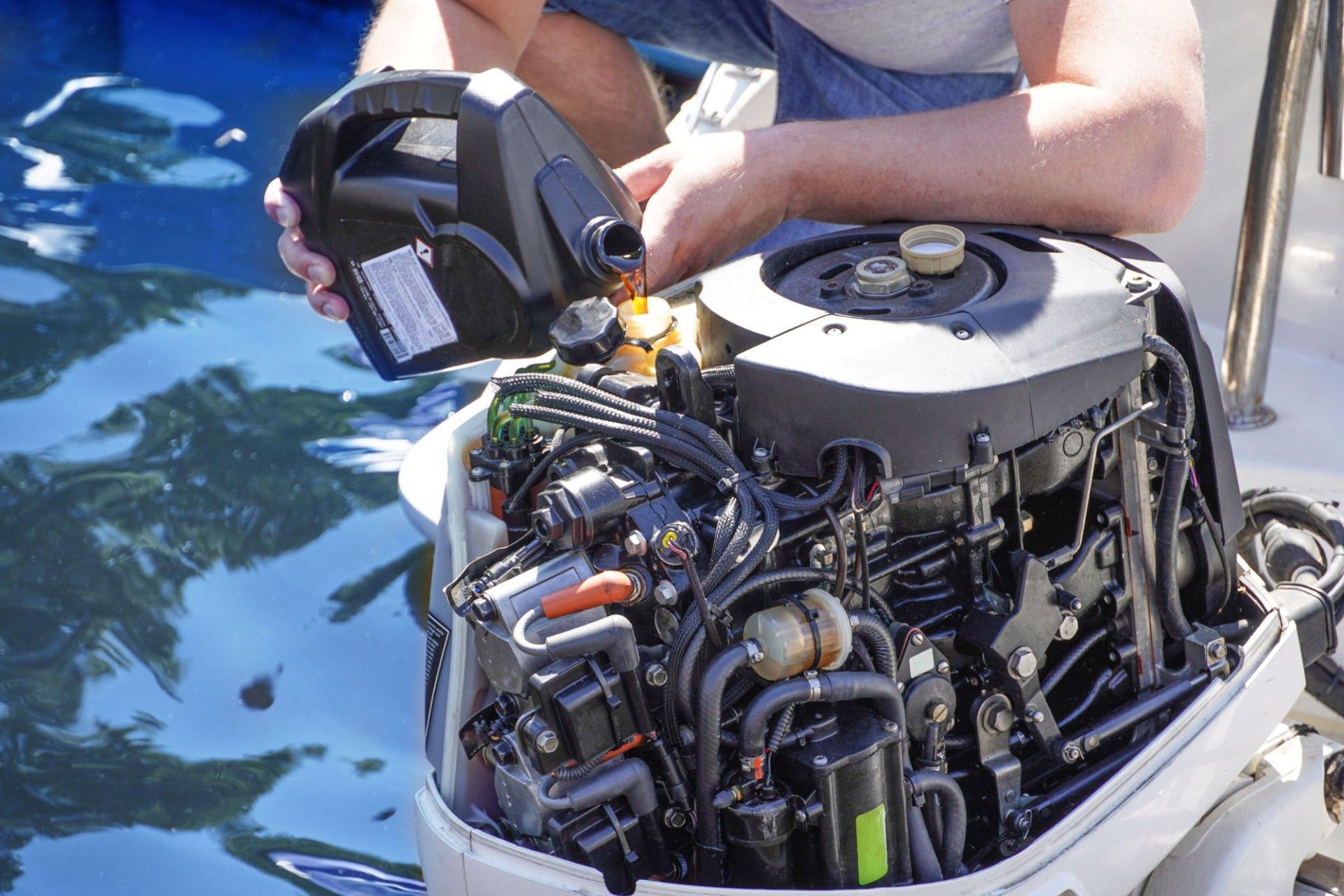

Alternator and Charger: Understanding the Issues

The alternator and charger are vital components of a marine electrical system, as they play a critical role in generating and regulating power. Understanding the potential issues that can arise with these components is essential for troubleshooting and maintaining a reliable electrical system on your boat.

An alternator is responsible for converting mechanical energy from the engine into electrical energy to charge the batteries while the boat is running. Problems with the alternator can result in insufficient charging or even complete failure. Common issues include worn-out brushes, faulty diodes, loose belts, or wiring problems. These problems can lead to reduced battery life, frequent battery replacements, or insufficient power to operate other electrical systems on the boat.

On the other hand, a charger comes into play when the boat is connected to shore power or a generator. It serves to replenish the battery bank by converting AC (alternating current) power into DC (direct current) power that the batteries require. Charger issues can stem from faulty wiring connections, damaged circuit breakers or fuses, or malfunctioning internal components such as rectifiers or voltage regulators. These problems can result in slow charging times, incomplete charging cycles, or overheating of the charger.

Understanding these potential issues with the alternator and charger allows you to address them proactively and ensure that your marine electrical system operates at its best.

Troubleshooting Tips for Alternator and Charger Problems

When faced with issues related to your boat's alternator or charger, there are various troubleshooting steps you can take to identify and resolve the problem. Here are some tips:

- Check connections: Start by inspecting all connections between the alternator/charger and the batteries. Loose or corroded connections can impede proper charging and lead to inefficient performance. Clean any corrosion using a wire brush and secure all connections tightly.

- Test voltage output: Use a multimeter to measure the voltage output of the alternator or charger. Compare the readings with the manufacturer's specifications to ensure they are within the recommended range. Low voltage output may indicate a problem with the component itself.

- Inspect belts and wiring: Examine the belts connecting the alternator to the engine and ensure they are properly tensioned. Inspect the wiring for any signs of damage, such as frayed insulation or loose connections. Damaged belts or wiring can lead to inadequate power transfer.

- Check for faulty diodes: Diodes in the alternator play a crucial role in converting AC into DC for battery charging. If one or more diodes fail, it can cause issues with charging efficiency. Diode testing requires specialized equipment and may be best performed by a professional.

- Monitor temperature: Overheating can adversely affect both alternators and chargers. Keep an eye on their temperature during operation and ensure proper ventilation to prevent overheating. If components become excessively hot, it may indicate an underlying problem that needs attention.

- Consult a professional: If troubleshooting steps do not resolve the issue or if you are unsure about performing further diagnostics, it is advisable to consult a qualified technician who specializes in marine electrical systems. They have the expertise and tools to diagnose and repair complex problems effectively.

Remember, addressing alternator and charger issues promptly is essential for maintaining the reliability and safety of your boat's electrical system. Regular maintenance and inspections can help identify potential problems early on, preventing costly breakdowns while out on the water.

Addressing Grounding Issues in Marine Electrical Systems

Grounding issues are among the most common problems encountered in marine electrical systems. These issues can lead to a range of electrical malfunctions, from intermittent equipment failures and erratic behavior to potential safety hazards. Addressing grounding issues is crucial for ensuring the proper functioning and safety of your boat's electrical system.

One common symptom of grounding issues is the presence of stray currents. Stray current occurs when electricity takes an unintended path, such as through metal fittings or other conductive materials on your boat. This can cause corrosion, electrolysis, and damage to sensitive electronic components. To address grounding issues related to stray currents, it's important to identify and eliminate potential sources of unintended electrical paths on your vessel.

Conduct a thorough inspection of all electrical connections on your boat. Check for loose or corroded connections, particularly at grounding points such as the engine block, battery terminals, and bonding system connections. Tighten any loose connections and clean off any corrosion using a wire brush or connector cleaner. Applying a dielectric grease or anti-corrosion spray can also help prevent future corrosion.

It's also essential to inspect the wiring on your boat for any signs of damage or deterioration. Frayed or damaged wires can contribute to grounding issues and pose a safety risk. Carefully examine all wiring harnesses, junction boxes, and circuit breakers for signs of wear or damage. If you notice any compromised wiring, replace it promptly with marine-grade wire suitable for your boat's electrical system.

Properly bonding metallic components on your boat can effectively address grounding issues by providing a designated path for stray current to flow safely back to its source. The bonding system connects all metal parts that come into contact with water, such as through-hull fittings, underwater hardware, and pumps. Checking the integrity of your boat's bonding system is essential to ensure effective grounding.

For example, if you have noticed galvanic corrosion on your boat's propeller or other metal components, it may indicate an issue with the bonding system. Using a multimeter, you can measure the resistance between various metal components to determine if there are any breaks in the bonding connection. If you detect high resistance or no continuity, it may be necessary to repair or replace corroded bonding wires.

Engaging a qualified marine electrician or technician is highly recommended when addressing grounding issues in your boat's electrical system. They have the expertise and tools to diagnose and resolve complex grounding problems effectively. Additionally, they can ensure that the necessary repairs or upgrades comply with relevant safety standards.

- Grounding issues in marine electrical systems are common and can lead to equipment failures, erratic behavior, and safety hazards. To address grounding issues, it is important to identify and eliminate potential sources of stray current, such as loose or corroded connections. Conduct a thorough inspection of all electrical connections and wiring, replacing any damaged components with marine-grade materials. Properly bonding metallic components can provide a designated path for stray current to flow safely back to its source. Engaging a qualified marine electrician or technician is recommended for diagnosing and resolving complex grounding problems. Regular inspections and maintenance of the electrical system can help prevent grounding issues from escalating into more significant problems.

What are some preventative measures I can take to avoid common electrical problems on my boat?

Regular inspection and maintenance of electrical connections, wiring, and components on your boat is crucial to avoid common electrical problems. Ensure all connections are clean and secure, checking for signs of corrosion or loose connections. Use marine-grade materials and connectors to prevent water damage. Additionally, investing in a reliable surge protector can safeguard against electrical surges, protecting your boat's electrical system.

Are there any specific safety precautions that should be taken when working on a marine electrical system?

Absolutely! When working on a marine electrical system, it is crucial to prioritize safety. Some essential precautions include wearing insulated gloves and eye protection, ensuring power is fully disconnected, using tools specifically designed for marine electrical work, and being cautious of potential electric shock hazards. According to the U.S. Coast Guard, in 2022 alone, there were over 500 reported incidents related to electrical failures on recreational boats. Following safety guidelines can significantly reduce the risk of accidents and ensure a smooth troubleshooting process.

How can I troubleshoot common electrical problems on my boat?

To troubleshoot common electrical problems on your boat, start by checking the battery connections for corrosion or loose connections. Next, inspect the fuses and circuit breakers to ensure they haven't tripped. If the problem persists, use a multimeter to test the voltage at various points in the system.

Are there any specific tools or resources available to help diagnose and repair marine electrical issues?

Yes, there are specific tools and resources available to help diagnose and repair marine electrical issues. One such resource is the "Marine Electrical Troubleshooting Guide" app, which provides step-by-step instructions and diagrams for troubleshooting various electrical problems on boats. Additionally, specialized tools like multimeters, circuit testers, and wire crimpers are essential for accurately diagnosing and fixing electrical issues on a boat. According to a survey conducted by the National Marine Electronics Association, 80% of boat owners found these tools and resources extremely helpful in resolving their marine electrical problems efficiently.

What are the potential dangers of ignoring or neglecting electrical issues on a boat?

Ignoring or neglecting electrical issues on a boat can lead to serious dangers and potential disasters. Firstly, it increases the risk of electrical fires, which can spread quickly and be difficult to control in a marine environment. According to the U.S. Coast Guard, electrical faults are one of the leading causes of boat fires. Secondly, malfunctioning electrical systems can cause power failures at critical times, leaving the boat stranded or in dangerous situations. Lastly, faulty wiring or grounding issues can give rise to electric shock hazards, potentially causing injuries or even fatalities. It is crucial to address any electrical issues promptly to ensure the safety and reliability of a boat's electrical system.